Known for its durability and ability to withstand harsh conditions, polyurethane foam is a popular choice for both air and water filtration.

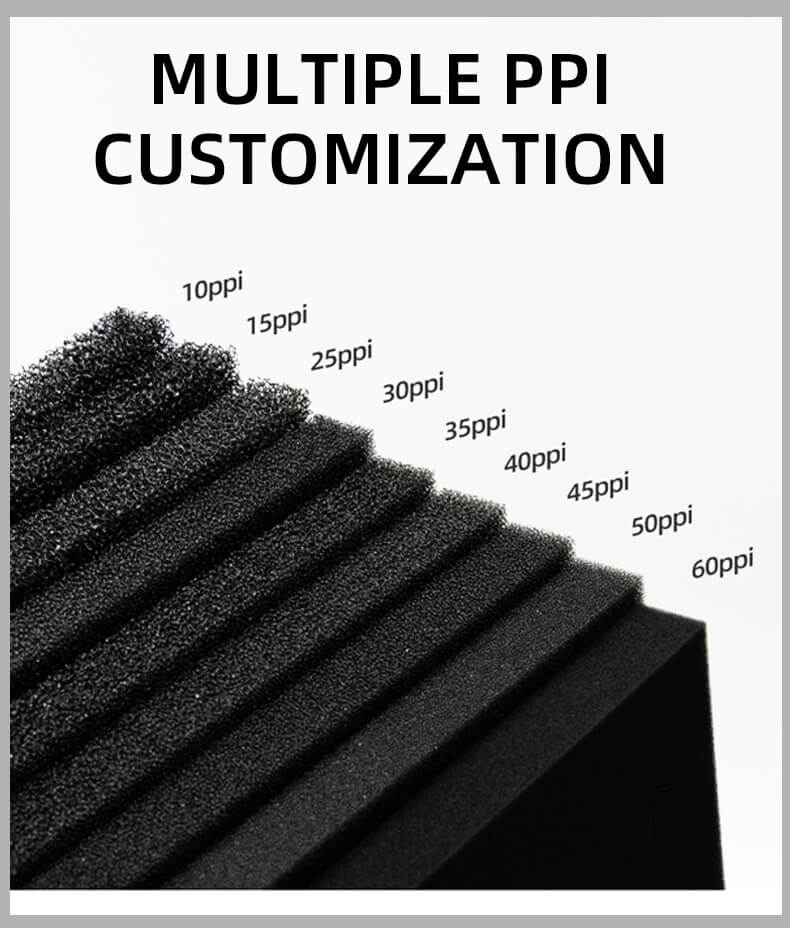

The pore size, measured in pores per inch (PPI), determines the size of particles that can be trapped.

Finer PPI values mean smaller pore sizes and better filtration.

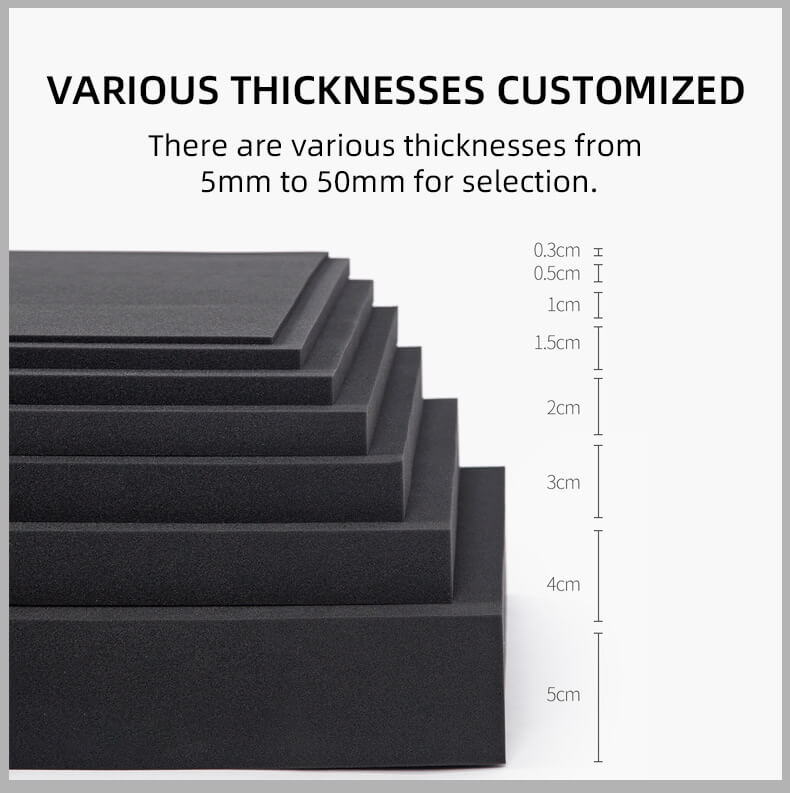

The thickness of the foam can affect its filtration capacity and airflow resistance.

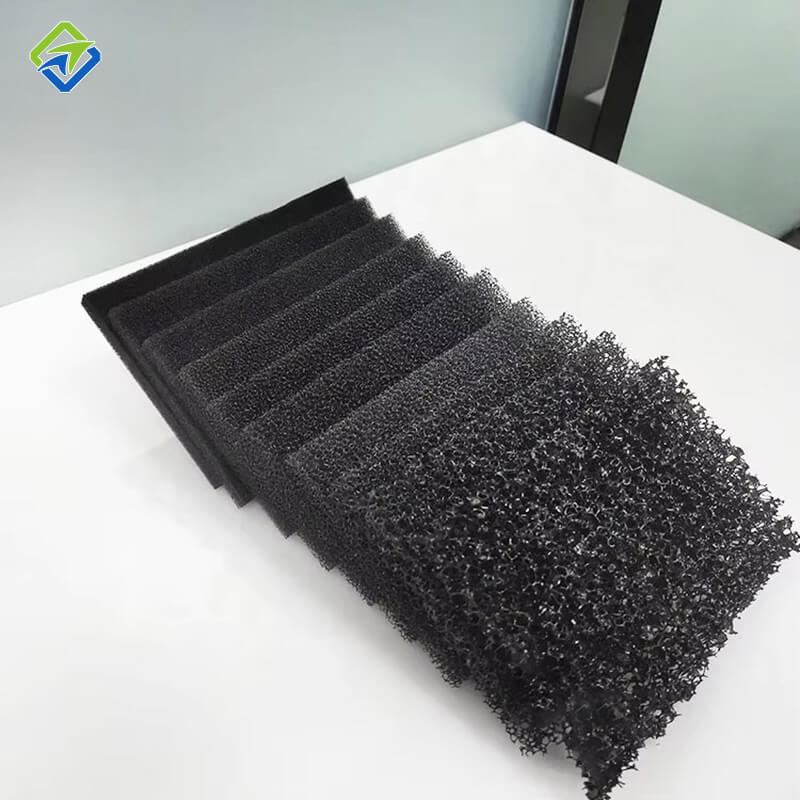

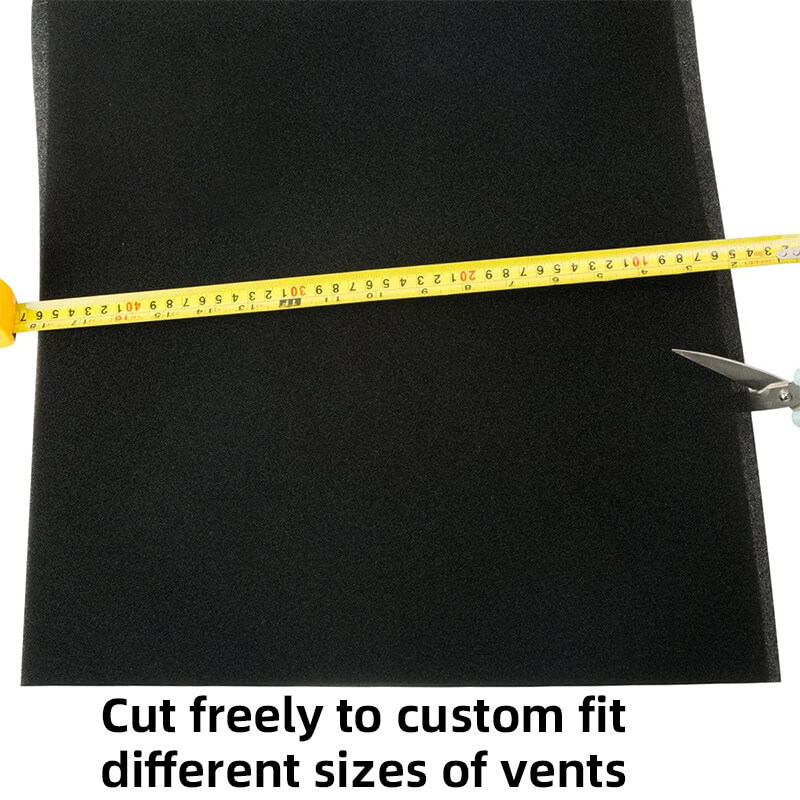

Filter foam is often available in sheets, rolls, or custom shapes to fit specific filter designs.

It is widely used in applications such as aquarium filters, HVAC systems, automotive filters, electronic equipment enclosures, and industrial machinery.

Description:

Typically made from polyurethane (PU),natural sponges,or regenerated fibers,with different materials selected based on the application.

The density of sponges varies depending on the usage, generally ranging from 10 kg/m3 to 50 kg/m3.

It has a rich porous structure, giving it excellent breathability and water absorption properties.

Typically suitable for temperatures ranging from -20℃ to 80℃; Some special sponges can withstand higher or lower temperatures.

Certain natural or biodegradable sponges have less environmental impact and meet sustainable development requirements.

Features:

High Water Absorption.

Softness.

Good Elasticity.

Durability.

Lightweight.

Functions:

Cleaning Function.

Liquid Absorption & Release.

Cushioning Protection.

Sound Insulation & Thermal insulation.

Medical Uses.

Filter Customization:

Explore our full range of air filters and find the perfect solution for your needs. Please send us your requirements to get custom sizes and thicknesses.